K&E Co., Ltd. pioneers a market for global expansion.

Our company produces USB 'Type-C' and 'I/O Connector Shell' products through our proprietary drawing technology, which allows for seamless, thinner construction, These products require advanced mold technology and process management skills beyond conventional mold techniques and complex side processing and shaping. They offer unparalleled competitiveness in quality, productivity and pricing compared to existing products.

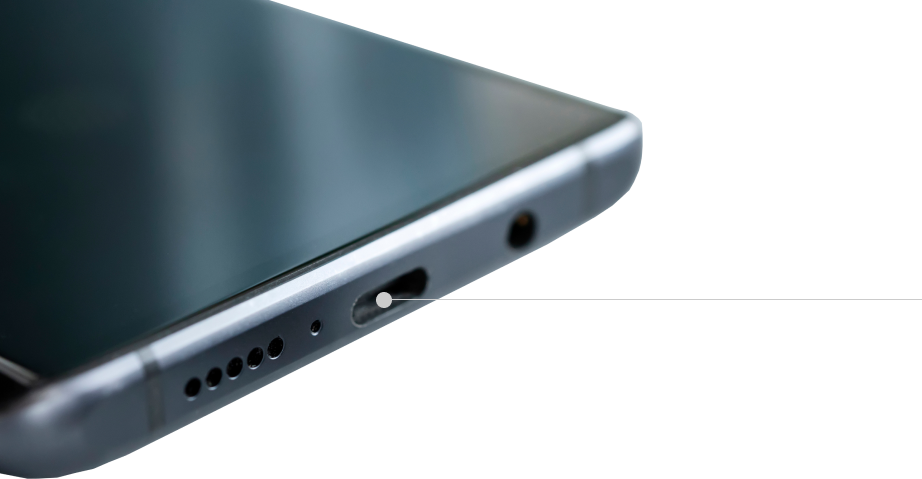

C-Type Socket-Drawing Shell Development Completed

Total Part Model Quantity

1 R&D Center / 3 Factories in Korea

/ 1 Corporation in Vietnam

By securing stable productivity with the USB Type-C mold manufactured through the drawing technology, it has been continuously applied to the Galaxy series of the company S since 2021.

Forming through circular drawing and then implementing complex shapes.

To ensure quality stability and mass production of complex designs, we've successfully developed and mass-produced these first in Korea through bold changes in the manufacturing process.

Hemming forming of waterproof FLANGE parts, challenging to implement with PRESS.

Waterproof Jack (USB Type-C)

TOP

TOP