K&E Co., Ltd. pioneers a market for global expansion.

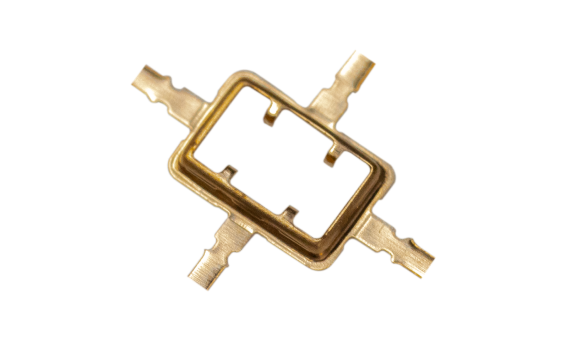

For efficient use of the 5G mm Wave high-frequency spectrum and stable communication, our company has developed the Full-Type Drawing Connector (Plug/Recep) capable of completely covering the external parts of the product's header and socket with metal shielding. This represents the pinnacle of ultra-thin sheet (0.08mm) inverse drawing technology and ultra-precision CAM molding technology for implementing three-dimensional shapes inside very small configurations.

B2B Connector-Plug/Recep Development Completed

Total Part Model Quantity

1 R&D Center / 3 Factories in Korea

/ 1 Corporation in Vietnam

These are connector parts for 5G that utilizes the reverse drawing technology of subminiature thin plate and the ultra-precision CAM molding technology that realizes a 3D shape inside the subminiature shape. They seal the product’s header and socket completely, and shields electromagnetic waves.

Subminiature thin plate (0.08mm) drawing technology, excellent in solidity and electromagnetic field compared to the bending type

CAM molding for implementing three-dimensional shapes inside tiny configurations

Structural design technology aimed at uniform quality Manufactured with a differentiated mold structure to meet the quality stability demanded by customers

Drawing Plug / Recep

TOP

TOP